Welding workshop

TIG, MIG and Laser Welding

In our welding shop we offer a service of excellence, where the combination of the latest technology and a highly trained team allows us to meet the needs and expectations of our customers in each project.

Our welding shop has 4 high performance equipments for all types of materials, in TIG, MIG and laser welding.

Welding work

Mig welding is characterized by its versatility and efficiency in joining different types of metals, on the other hand, Tig welding stands out for its ability to produce high quality welds on delicate and thin metals, thanks to its controlled process that minimizes spatter and ensures a strong and durable joint.

Finally, laser welding is an advanced technique ideal for jobs that require high precision and clean joints.

Differences between TIG welding and MIG welding

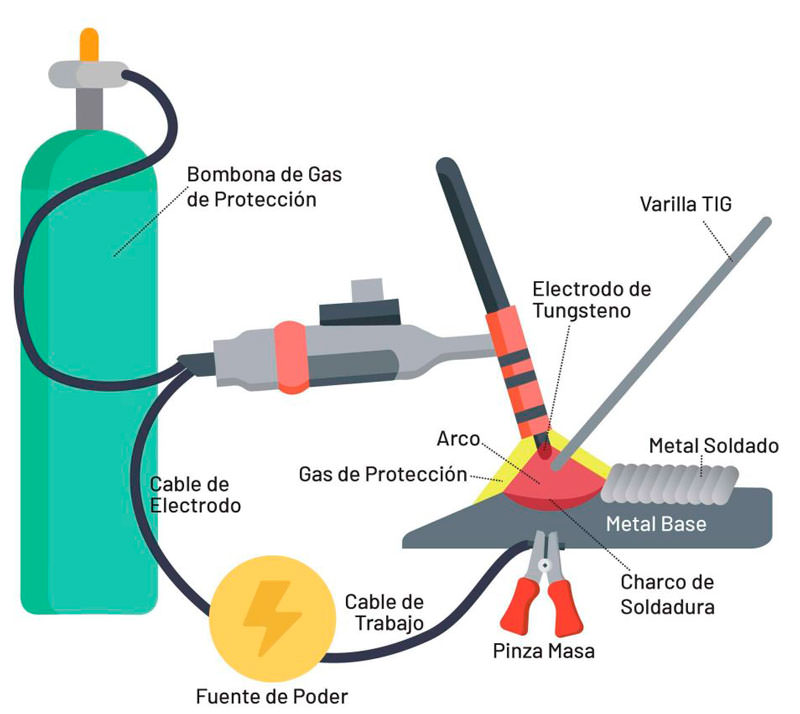

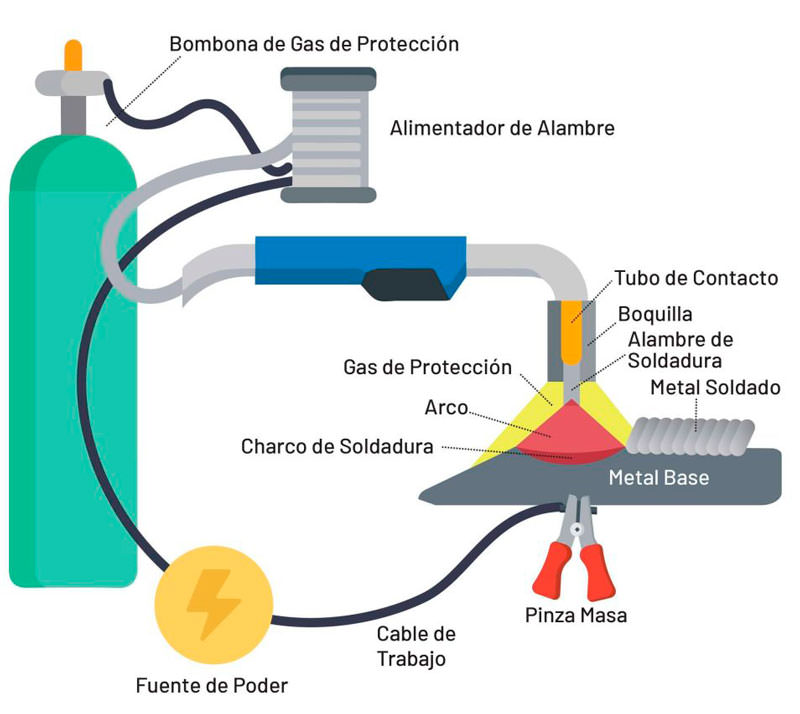

Electrodes

TIG welding uses a tungsten electrode that is not consumed during the welding process, while MIG welding uses a metal electrode that serves as filler material for the weld and is consumed during welding.

Filling material

TIG welding requires a separate filler material in rod or wire format because the electrode is not consumed. MIG welding, on the other hand, delivers the filler material through the electrode.

Difficulty

TIG welding is considered more difficult than MIG welding because the tolerances have to be tighter between the electrode, filler rod and work piece.

Uses

TIG welding can be applied to almost any metal, from steel to aluminum and exotic alloys. It is used when it is necessary to make the pieces sideways and then finish the work with some welding.

It is also suitable for welding thin metals and has a stronger, corrosion-resistant finish. In addition, the system can be automated, mechanically controlling the gun and the metal.

MIG welding was developed for welding non-ferrous metals, but can be applied to steel and aluminum structures. On the other hand, there are different ways to perform MIG welding, manually, automatically or semi-automatically. It can be used for small and medium thicknesses, and it is possible to weld in any position.

TIG welding

MIG welding

Laser welding equipment

In ASSOMEC we have updated our welding section with advanced technology. We incorporate state-of-the-art fiber laser welding and a self-developed common/oscillating welding gun with safety detection and seam width adjustment. This system is ideal for welding thin sheets, offering:

- Easy welding on large objects, long distances and hard-to-reach places.

- High strength and thin seams without deformation, polishing or consumables.

- Welding speed 5-10 times faster than conventional plasma or argon arc welding.

- 10-20% less energy consumption than the traditional process.

- Easy operation, long service life and high safety.

If you can think of it… We can do it

TIG welding, MIG welding and LASER welding workshop

We offer laser, TIG and MIG welding services for companies, workshops and individuals. We also provide services to other machining companies.

We guarantee short response times adapted to each project and need.

Production process control with ERP

The use of an ERP system allows us to know the status of each order: completed parts, pending parts and the progression of each reference.

Express quote (online)

We stand out for our quick response in the preparation of quotations and delivery of orders, adapting to the demands of short deadlines of our customers thanks to our production capacity and large stock of materials in warehouse.

Customer loyalty and satisfaction

Close contact with AssoMec staff, fast delivery and quality services promote long-lasting relationships with customers, resulting in mutual benefit and effective problem solving.

01_

Turning

Metal and other materials

02_

Water cut

Water jet for cold cutting

03_

Welding Workshop

TIG, MIG and Laser Welding