Metrology and Quality

In the metrology and quality department we ensure that all manufactured or repaired products meet the established quality standards.

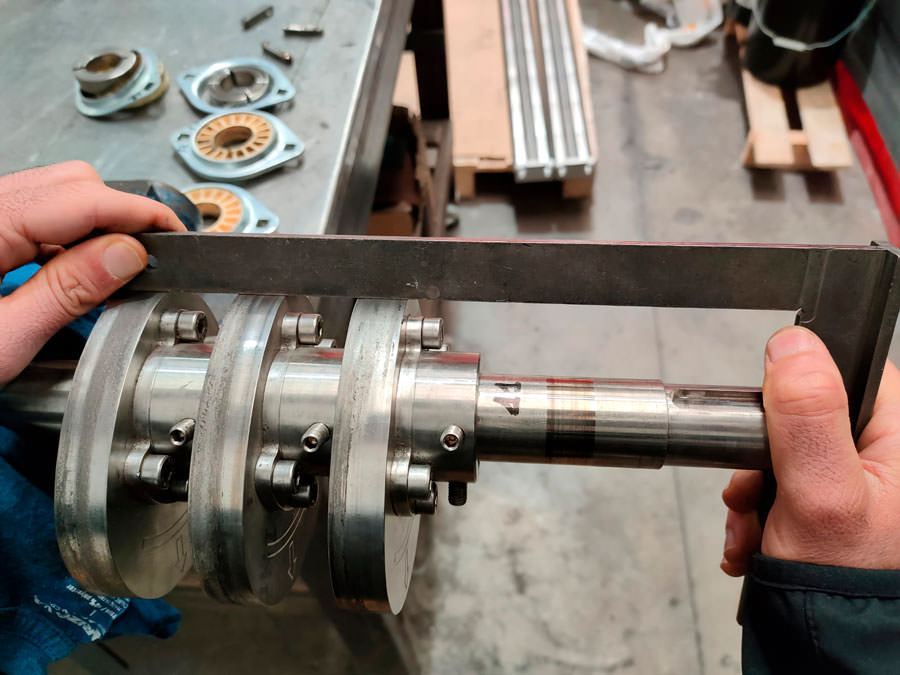

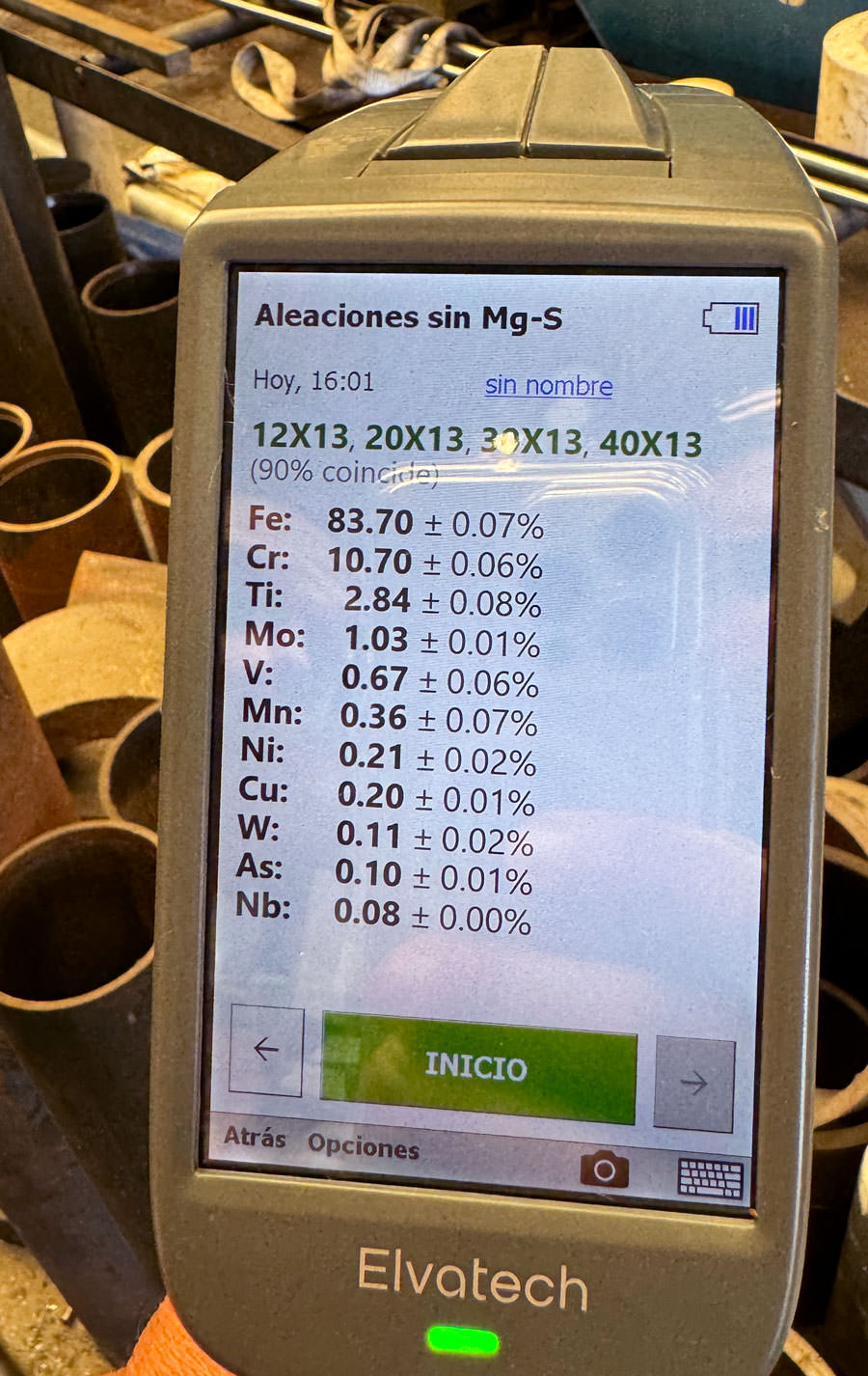

We perform inspections and tests to verify the dimensions, accuracy and functionality of the manufactured parts.

Testing and inspection.

In the metrology and quality department, we carry out exhaustive inspections on manufactured parts to ensure that they meet the established design specifications.

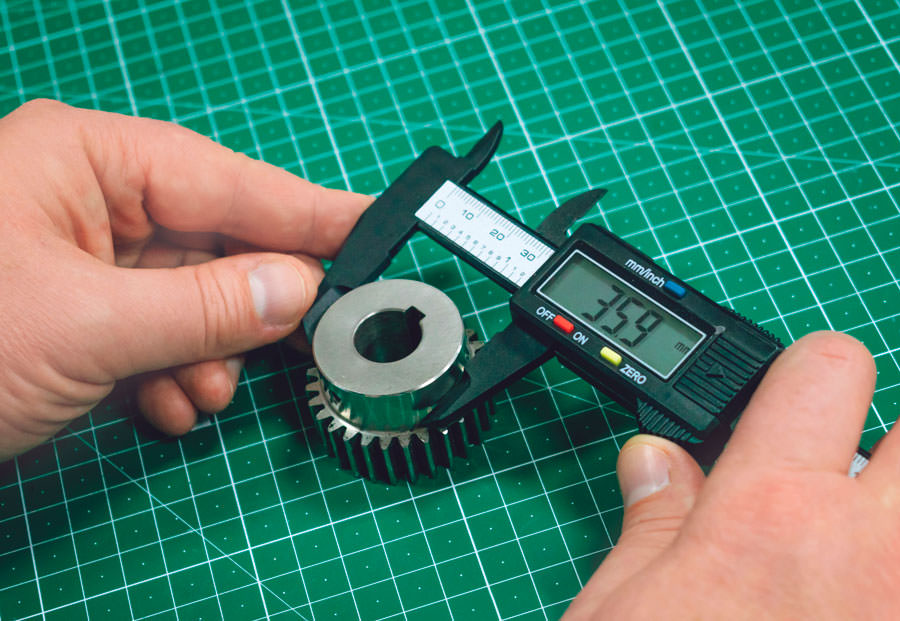

We use high-precision measuring equipment, such as calipers, micrometers, and coordinate measuring machines (CMM), to verify accurate part dimensions.

In addition, we perform functionality tests to ensure that the parts meet performance requirements.

If you can think of it… We can do it

Metrology and Quality Department

Our goal is to ensure that each manufactured part meets the highest quality standards and satisfies the needs and expectations of our customers.

Production process control with ERP

The use of an ERP system allows us to know the status of each order: completed parts, pending parts and the progression of each reference.

Express quote (online)

We stand out for our quick response in the preparation of quotations and delivery of orders, adapting to the demands of short deadlines of our customers thanks to our production capacity and large stock of materials in warehouse.

Customer loyalty and satisfaction

Close contact with AssoMec staff, fast delivery and quality services promote long-lasting relationships with customers, resulting in mutual benefit and effective problem solving.

01_

Turning

Metal and other materials

02_

Water cut

Water jet for cold cutting

03_

Welding Workshop

TIG, MIG and Laser Welding